Why Tribology Matters When Calculating Bearing Performance

Leave a CommentFirst, What is Tribology?

Tribology is the study of friction and wear on surfaces and materials that are in motion. Bearings are the perfect example of products that would require some background in tribology, since they are constantly rubbing against other items in their everyday function.

Bunting Bearings has always been at the forefront of bearing calculations including PV wear and friction data, and when we required independent verification on how effective a bearing material our new lead free ECO Bronze material was, we turned to the leading US tribology expert, Dr. Robert Adams.

Dr. Adams’ doctoral research was focused on characterizing plane bearing materials’ PV friction and wear performance profiles. Dr. Adams applied his knowledge to develop a tribometer that reduced the time needed to obtain reliable PV wear and friction test results. Dr. Adams’s company, Tribis Engineering Inc., is now finalizing all the PV data that will show that ECO Bronze is the first real cost competitive material to current leaded and lead free bronze bearing materials.

Bunting will be releasing tribological data on many of our bronze compounds in the near future.

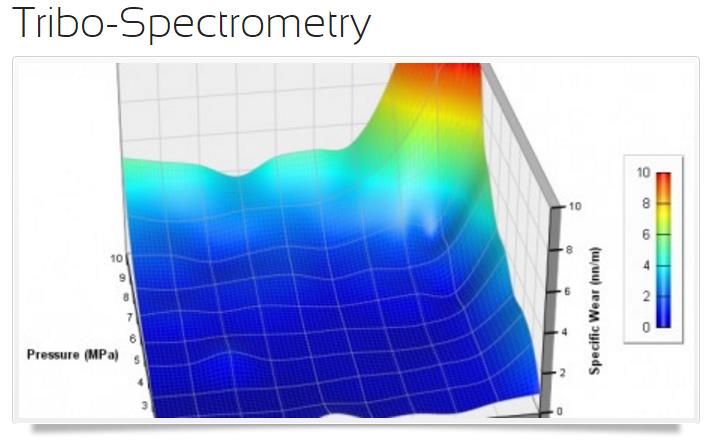

There is not a single “best” bearing material and surface combination. Understanding how the various materials compare under these changing conditions makes it possible to select the “best” bearing material and surface combination for a particular application.

Tribo-spectrometry helps us to understand the particular friction and wear behavior of differing materials, and make the right choices for current needs.