Bronze vs. Plastic Bushings: What’s the Difference?

Leave a CommentBearings and bushings come in a range of sizes and can be made out of metal, plastic composites, or a combination of the two. This variety means you can find exactly what you need for a specific project; however, with so many choices, how do you decide the best option for you? Plastic and metal both have unique characteristics and advantages, and your choice will depend on the project, your budget, and more.

Plastic Bushings

Affordable and versatile, plastic bushings are used for many different industries, such as agricultural, medical, and machines, including fitness equipment, lawn mowers, food processing machinery, pumps, and valves. Because production of these bushings is fast and cost-effective, choosing plastic over metal could save you money depending on the type of plastic you choose.

Engineered plastic bushings have a predictable wear rate, meaning you can accurately calculate the service life for an application based on a tribological test database. You can accurately determine their service life span and replace them before they malfunction, knowing you used them exactly as long as you could. That means less guesswork, fewer errors, and more time and money saved.

Plastic bushings are corrosion and chemical resistant as well as self-lubricating—no grease required! If you think plastic is unable to stand up to heat, you might be surprised to learn these bushings can withstand temperatures up to 900°F for short periods. Over longer periods, they can perform in temperatures up to 482°F.

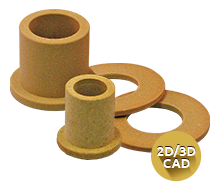

Bronze Bushings

With all the benefits of plastic, where does that leave metal? Bronze remains a popular choice for bushings because it’s available in so many alloys and compositions, expanding its reach into even more applications. A bronze bushing is harder and less likely to break or deform than those made of other materials.

Like plastic, bronze bushings are long-lasting and corrosion resistant. As noted above, their strength allows them to hold up under impact. One potential disadvantage is that metal requires a lubricant to reduce friction and prolong the bearing’s service life. Oil or grease must be applied at installation and during operation.

Still, the benefits may outweigh that small inconvenience. Bronze bushings are common in low-speed, high-load as well as high speed, low load industrial applications, including:

- Iron and steel manufacturing

- Food processing

- Valves

- Automobiles

Let’s take a closer look at two common bronze bushing materials:

- SAE841 Sintered Bronze:These oil-impregnated bronze bushings can be used with both high and low speeds, as well as high and low temperatures, depending upon the type of oil. SAE841 is also used for applications requiring food-grade quality.

- Cast Bronze:The extra corrosion resistance with these alloys (typically bronze with tin, aluminum, or silicon) makes it especially useful in wet environments.

Bunting Bushing Solutions

Whether you need bronze or plastic bushings, Bunting Bearings can fill your needs. We have engineered parts available in nylon, PTFE, various bronze alloys and more:

- Vespel®: This brings the best of plastic, metal, and ceramic together for a bearing that can manage high speeds, heavy loads, and high temperatures.

- Nylatron: Cost-effective and self-lubricating, this is a nylon modified with molybdenum disulfide lubricant powder.

- PTFE: Four different PTFE material bushings are held in stock including a non-toxic FDA compliant range.

- BU: This unique composite features a steel backing and a bronze layer impregnated with PTFE for a strong mechanical bond.

- Cast Bronze: A full range of leaded tin bronze bearings are in stock plus a full range of sleeve and flanged bushing made from ECO BRONZE which in independent tests proved to be superior to other cast lead-free materials.

If you’re not sure which bearings are right for you, contact us. We’ll answer your questions about the advantages of each option and help you figure out which one will work best for your application.